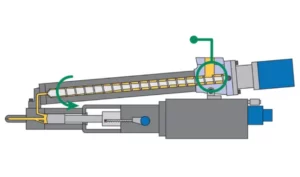

The conical twin screw extruder is an important piece of machinery in the plastic processing industry. It is used to melt and mix polymer materials, and then extrude the mixture through a die to form the desired shape. One of the crucial factors that determine the quality of the final product is the screw clearance, which is the space between the two screws. In this article, we will discuss how to adjust the screw clearance of a conical twin screw extruder.

Introduction

The screw clearance plays a significant role in the extrusion process, as it affects the flow of the polymer material, the mixing, and the quality of the final product. If the screw clearance is too tight, the material may become clogged, and if it is too loose, the material may not be mixed adequately. Therefore, it is essential to have a proper screw clearance to achieve optimal performance from the conical twin screw extruder.

What is the Screw Clearance in Conical Twin Screw Extruder?

The screw clearance is the space between the two screws in a conical twin screw extruder. It is measured in millimeters and is crucial for the proper functioning of the extruder. The screw clearance should be set to the optimal level to ensure that the polymer material is mixed and melted properly, without becoming clogged.

Why is it Important to Adjust the Screw Clearance?

Adjusting the screw clearance is essential for several reasons:

- To maintain the optimal flow rate of the polymer material.

- To prevent clogging of the material.

- To ensure proper mixing of the material.

- To produce a consistent and high-quality final product.

Steps to Adjust the Screw Clearance of Conical Twin Screw Extruder

Adjusting the screw clearance of a conical twin screw extruder can be done in the following steps:

- Turn off the extruder and let it cool down.

- Remove the screws from the extruder.

- Clean the screws thoroughly to remove any material residue.

- Measure the current screw clearance using a feeler gauge.

- Adjust the screw clearance by moving the screws closer together or further apart, as needed.

- Reinstall the screws and tighten the screws to the proper torque.

- Turn on the extruder and perform a trial run to check if the screw clearance has been set correctly.

- Repeat the adjustment process, if necessary, until the optimal screw clearance has been achieved.

Tips for Adjusting the Screw Clearance

Here are some tips to help you adjust the screw clearance of a conical twin screw extruder:

- Always work with a cool extruder to avoid any risk of injury.

- Use a feeler gauge that is suitable for the size of the screws.

- Tighten the screws to the proper torque to prevent any movement during the extrusion process.

- Perform a trial run after adjusting the screw clearance to check if the setting is correct.

FAQs

Q: How do I know if the screw clearance is too tight or too loose?

A: If the screw clearance is too tight, the material may become clogged, and if it is too loose, the material may not be mixed adequately. The optimal screw clearance can be determined by trial and error, or by referring to the manufacturer’s specifications.

Q: How often should I adjust the screw clearance of my conical twin screw extruder?

A: The frequency of adjusting the screw clearance depends on several factors, such as the type of material being processed, the speed of the extruder, and the conditions of operation. It is recommended to check the screw clearance regularly and adjust it if necessary to ensure optimal performance.

Q: Can I adjust the screw clearance on my own or do I need a professional?

A: Adjusting the screw clearance is a relatively straightforward process, and it can be done by an experienced operator. However, it is always best to consult the manufacturer’s instructions or seek the help of a professional if you are unsure.

Conclusion

The screw clearance of a conical twin screw extruder plays a critical role in the quality of the final product. Proper adjustment of the screw clearance is essential to achieve optimal performance and prevent clogging and inadequate mixing of the polymer material. This article provides a step-by-step guide to adjusting the screw clearance of a conical twin screw extruder and answers some common questions about this process. By following these guidelines, you can ensure that your conical twin screw extruder operates at its best and produces a consistent, high-quality product.

Contact Us for Your Customized Screw Barrels Needs

If you’re in need of customized conical screw barrels, look no further than our company. Contact us today to discuss your requirements and see how we can meet your needs. Our team of experts is ready to assist you with any questions you may have.