The injection screw and barrel are key components in plastic and rubber processing industries. Be it OEM or ODm, conical or parallel screws, and barrels are the backbone of the injection and extrusion machines. The performance of the injection molding machine significantly depends on these parts.

Modern screw and barrel manufacturers make it possible to roll threads with high precision in a tight tolerance. A smaller tolerance is proportional to the durability of a special tool for making threads.

Jinhua is a professional injection screw and barrel manufacturer. The popular size of our injection molded screws and barrels are:

1.¢16

2.¢30

3.¢60

4.¢70

5.¢80

6.¢90

7.¢110

8.¢170

9.¢220

10.And others

Similarly, Jinhua offer following injection molding screw and barrels:

- Injection molding screw and barrel

- Injection molding barrel

- Screw for injection molding machine

The injection molding screw and barrel are significant in injection molding machines performance. With injection molding screw and barrels, transforming raw resin pellets into high-quality plastic products is extremely convenient.

It won’t be wrong if we say that screw is the driving force behind this transformation. Therefore, the quality of screw and barrel material is very important here. Only high-quality screw and barrels withstand the rigors of the molding process.

Injection Molding Screw and Barrel Tolerance

Screw Diameters

The standard tolerance for the outer diameter of a screw is +/- 0.001 inches per inch of diameter. For example, a screw with a 2-inch diameter would have a tolerance of +/- 0.002 inches.

Screw Flights

The distance between the interior diameter of the barrel and the outside diameter of the screw flight is known as the flight clearance. Subsequently, it is usually defined as ranging between 0.004 and 0.006 inches per inch in diameter. For example, the flight clearance for a 2-inch screw would be between 0.008 and 0.012 inches.

Screw Length

The standard tolerance for the screw length is +/- 1/32 of an inch.

Barrel Diameters

Generally, the barrel’s internal diameter is defined with a tolerance of +/- 0.001 inches per inch of diameter. For example, a barrel with a diameter of 2 inches has a tolerance of +/- 0.002 inches.

Barrel Straightness

Usually, a tolerance of +/- 0.001 inches per inch of length is specified for barrel straightness.

Barrel Concentricity

A tolerance of +/- 0.001 inches is provided for barrel concentricity.

Screw and Barrel Matching

The screw and barrel should be appropriate for one another for optimal results. The screw flight clearance must be within the required tolerance range to enable effective melting and mixing of the plastic. The screw and barrel should also be tightly packed with respect to one another to avoid leaks and ensure smooth melt quality.

Tolerance Effects on The Injection Molding Process

A smooth and quality injection molding process depends on the screw and barrel dimensions being held to a tight tolerance. Tolerance that is excessively loose can cause issues, including:

- ·Leakage

- ·Poor melt quality

- ·Poor part quality

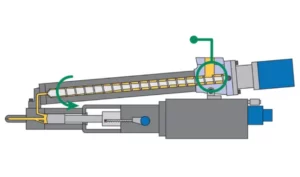

The extrusion system is made up of a barrel and a screw. The barrel operates under similar conditions to the screw, including:

- ·High pressure

- ·High temperature

- ·Extreme wear

- ·Specified corrosion

The barrel also acts as a heat transfer tool throughout the extrusion process, either directing heat toward the material or away from it. The barrel and machine head must both have a heating and cooling system installed.

Barrel structure

Integral barrels and integrated barrels are the two types of barrels with respect to the general structure.

(1) Integral barrel

The construction makes it simple to assure superior manufacturing and assembly accuracy. It also makes it easier to install, assemble, and disassemble the heating and cooling system, and the heat is distributed comparatively equally in the axial direction. Therefore, the processing and manufacturing requirements for this type of barrel are higher.

(2) Combined barrel

A combined barrel is made up of various barrel sections. It can be used with both vented and experimental extruders. The first is used to make it easier to adjust the barrel’s length to fit screws with various aspect ratios, while the second is used to set up an exhaust section.

Combined barrels can also be used for collecting and gathering materials, which is useful for small to medium-sized factories. However, the combined barrel actually needs highly precise processing. Flange bolts are often used to secure different barrel parts of the combined barrel together.

As a result, the barrel heating is less consistent, and more heat is lost. The installation and maintenance of the heating and cooling systems are also extremely challenging.

(3) Bimetal barrel

Many barrels have an alloy steel bushing inside the body of cast or carbon steel to not only satisfy the material requirements but also protect precious metals. After some wear, the bushing can be removed and replaced. The bushing and barrel must work perfectly together to guarantee that heat conduction on the entire barrel wall is unaffected.

The bushing and barrel should not move with respect to one another, and they should be simple to remove. This means choosing the right fit with accuracy.

Use of Barrel in An Injection Molding Machine

The barrel ensures perfect heat transfer to the plastic material and provides the screw with suitable confinement.

It has heating elements that keep the temperature needed for melting the plastic pellets at an even level. The barrel is also important to the homogenization procedure because it allows thorough mixing and eliminates any defects in the molten plastic.

The barrel additionally offers the required pressure to force the molten plastic substance via the nozzle and into the mold.

Injection Molding Tolerance

The most important elements for design and production in injection molding are precise measurements and tight tolerances. The components may work well or even fail if adhered to adequately within a plan.

Tight tolerance is a vital part, especially for complex plastic injection-molded parts. The very close tolerance for injection molding is +/- 0.025mm, whereas the average tolerance is +/- 0.1mm.

Clearances and Tolerances in Screw and Barrel

Tolerances and clearances in injection molding machines are vital to these parts’ efficient and accurate operation. The screw barrel ensures that the final product is produced with a smooth surface finish at the given rate.

Manufacturers and users of plastic processing equipment must pay careful attention to managing clearances and tolerances to ensure the effective and reliable operation of the machinery.

The efficiency and excellence of screw and barrel systems in plastic processing machines must be maintained through routine maintenance, inspection, and following manufacturer requirements.

Conclusion

In conclusion, it is crucial to consider the screw and barrel tolerance of injection molding to maintain the overall manufacturing process. Subsequently, the selection of material also plays a pivotal role. Therefore, always remember that precision and tolerance have a major role in final product quality.