Screw barrels are an essential component in various industrial processes, and their efficiency can greatly impact the overall productivity of a production line. In this article, we will explore several ways to improve the production efficiency of screw barrels to ensure that your production runs smoothly and effectively.

What is the Screw Barrel

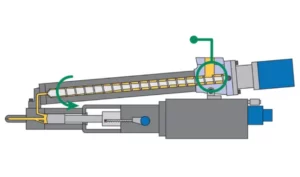

The screw barrel is a critical component in many production processes, particularly in the plastics and rubber industries. It is responsible for melting and conveying the raw material from the hopper to the mold or die. The screw barrel is typically composed of a screw and a barrel, which are both made from high-quality steel and other materials.

Factors that Affect Screw Barrel Efficiency

There are several factors that can affect the efficiency of screw barrels, including the quality of the raw materials, the design of the screw and barrel, and the operating conditions. Other factors include the temperature, pressure, and speed at which the screw barrel operates. Understanding these factors is crucial in ensuring that the screw barrel operates at its maximum efficiency.

How to Improve the Production Efficiency of Screw Barrels

Improving the Quality of Raw Materials

One of the most important steps in improving the production efficiency of screw barrels is to use high-quality raw materials. This includes using high-quality steel and other materials for the screw and barrel, as well as using the right type of raw materials for the specific application. By using high-quality raw materials, you can ensure that the screw barrel operates at its maximum efficiency and does not suffer from excessive wear and tear.

Optimizing the Design of the Screw and Barrel

Another key factor in improving the production efficiency of screw barrels is to optimize the design of the screw and barrel. This includes ensuring that the screw and barrel are properly aligned, and that the screw is designed to efficiently convey the raw material. Proper alignment helps to prevent excessive wear and tear on the screw and barrel, while screw barrel manufacturer efficient screw design helps to minimize energy consumption and increase the overall efficiency of the screw barrel.

Monitoring Operating Conditions

To ensure that the screw barrel operates at its maximum efficiency, it is important to monitor the operating conditions. This includes monitoring the temperature, pressure, and speed at which the screw barrel operates, and making adjustments as necessary to optimize these conditions. By monitoring the operating conditions, you can quickly identify any problems and take corrective action to improve the efficiency of the screw barrel.

Regular Maintenance

Regular maintenance is also an important factor in improving the production efficiency of screw barrels. This includes regularly inspecting the screw and barrel, and replacing any parts that are worn or damaged. Regular maintenance also helps to ensure that the screw barrel operates at its maximum efficiency, and helps to prevent unexpected downtime.

Conclusion

In conclusion, improving the production efficiency of screw barrels is crucial in ensuring that your production runs smoothly and effectively. By using high-quality raw materials, optimizing the design of the screw and barrel, monitoring operating conditions, and performing regular maintenance, you can ensure that your screw barrel operates at its maximum efficiency.

FAQs

-

How often should I perform maintenance on my screw barrel?

It is recommended to perform maintenance on your screw barrel on a regular basis, depending on the usage and operating conditions. A typical maintenance schedule may be every 3 to 6 months, but this can vary based on the specific application.

-

Can I use low-quality materials for my screw barrel?

Using low-quality materials for your screw barrel is not recommended, as it can lead to excessive wear and tear and decreased efficiency. Using high-quality materials can ensure that the screw barrel operates at its maximum efficiency and reduces the likelihood of unexpecteddowntime.

-

What happens if the screw and barrel are not aligned properly?

If the screw and barrel are not aligned properly, it can lead to excessive wear and tear on the screw and barrel, and can result in reduced efficiency. Proper alignment helps to prevent these problems and ensures that the screw barrel operates at its maximum efficiency.

-

Can I improve the efficiency of my screw barrel by simply increasing the speed of operation?

Increasing the speed of operation can improve the efficiency of the screw barrel, but it is not the only factor to consider. It is also important to ensure that the other operating conditions, such as temperature and pressure, are optimized to prevent excessive wear and tear on the screw and barrel.

-

Can I use the same screw barrel for different materials?

Using the same screw barrel for different materials is not recommended, as different materials may have different melting points and flow characteristics. Using a screw barrel that is specifically designed for the material you are processing can help to ensure that the screw barrel operates at its maximum efficiency and reduces the likelihood of problems.